This document from Tapis Rouge outlines the complete production cycle for both handcrafted and machine-made rugs, detailing every stage from choosing the pile fibers and blends, to spinning the yarn, dyeing, constructing the rug, adding texture, and completing the finishing and warp.

OUR MANUFACTURING STEPS:

- Idea & Design Development

- Sample Sketching

- Yarn Selection

- Fabric Dyeing

- Technique

- Initial Washing

- Knot Leveling

- Precision Carving & Finishing Details

Idea & Design Development

We derive inspiration from a multitude of sources, ranging from the captivating allure of nature, architectural wonders, to studies of elaborate tapestries, historical fabric collections, and cultural legacies. Each pixel is transformed into knots that merge historical identities with visions of potential future contexts.

Sample Sketching

From subtle color transitions to the most delicate lines or varying pile heights, each new design represents a marvelous creation. We provide an extensive selection of carpet samples, enabling our clients to observe the intricate details prior to ordering a full-sized carpet or a bespoke design.

Yarn Selection

Our manufacturing process is eco-friendly and features handcrafted pieces made with uniquely dyed threads. Once our designers approve the colors, production truly begins.

Fabric Dyeing

Our moral obligation is deeply rooted in maintaining genuine, traditional methods from history, which is why we persist in using natural recipes that reduce the environmental footprint of dyeing the yarns.

Technique

Our carpets are meticulously hand-tied, sculpted, and cleansed by our skilled artisans in Nepal, utilizing only eco-friendly instruments and methods.

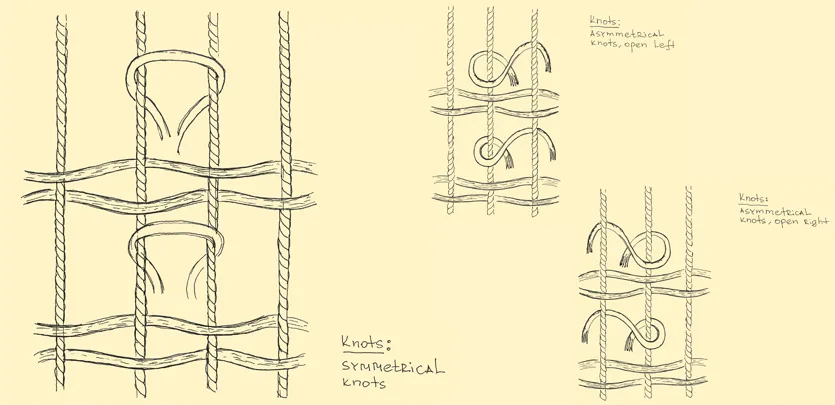

Hand-knotted

A meticulous hand-weaving process, performed on either vertical or horizontal looms, involves a carefully chosen contraption typically crafted from durable wood, serving as the foundation for the entire production process. Talented artisans painstakingly tie individual knots by hand, securing each fiber strand into the rug’s weft threads. This method allows for various finishes, ranging from simple to sophisticated loop piles, as well as the combination of different natural fibers such as wool, silk, and bamboo silk, each boasting distinct qualities that enhance the texture and durability of the final product. Blending diverse fibers adds complexity and richness to the design, resulting in a visually striking and tactilely pleasing rug. Intricate designs often necessitate a higher knot density per unit area of the rug, leading to longer production times but yielding the finest and highest-quality outcome.

Hand-Tufted

A rug-making technique executed by skilled craftsmen utilizing specialized handheld tufting guns or needles. These implements facilitate precise yarn insertion through a meticulously stretched canvas, firmly secured to a sturdy frame. As the yarn is intricately pushed through the canvas, it forms loops or piles on the rug’s surface, allowing craftsmen to create unique textures and designs. The intricacy of the design is adjusted by manipulating knot density, determining the number of yarn loops per unit area, ranging from sparse, open designs to densely packed, plush patterns. Knot density is a crucial technical aspect meticulously adjusted by craftsmen to achieve the desired visual and tactile effect. The selection of colors for the yarn also plays a key role, offering a wide range of creative possibilities. While the production timeline for hand-tufted rugs is relatively shorter compared to methods like hand-knotting, it remains a labor-intensive process due to its manual nature. Hand-tufted rugs often require skilled craftsmanship and premium natural materials.

Initial Washing

Following the completion of the hand-knotting process, we employ specialized equipment to thoroughly wash the rug, after which it is stretched for drying.

Knot Leveling

In order to maintain precise alignment with the pattern depicted in the sketch, an alignment and stretching phase is imperative during the production of our rugs. This meticulous process is overseen by master artisans due to its requirement for exacting precision.

Precision Carving & Finishing Details

This stage is pivotal and exhilarating, as it brings the design to fruition, unveiling its various dimensions, shadows, and pile heights through meticulous carving.